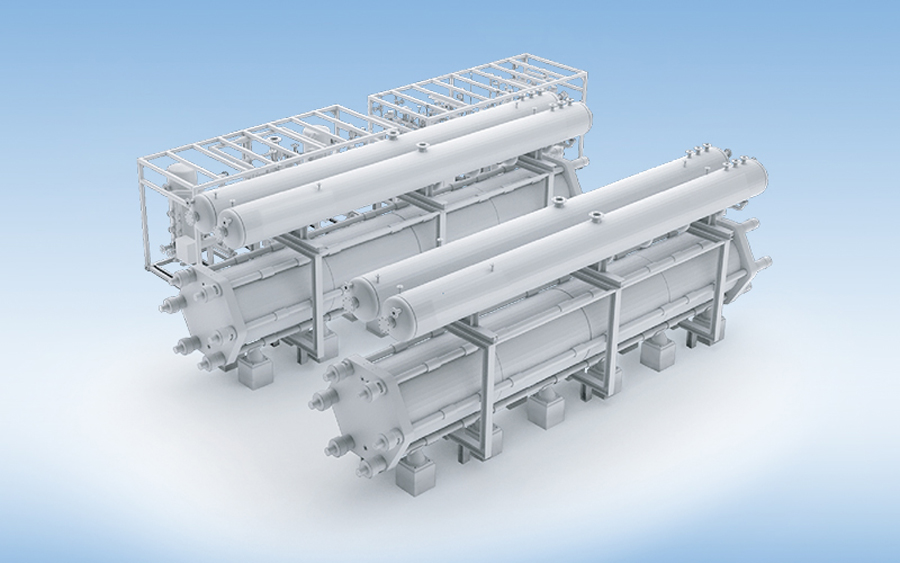

ALKALINE (ALK) ELECTROLYZERS

Our (ALK) alkaline electrolyzer is a new type of alkaline electrolyzed water hydrogen production equipment, which has the characteristics of modularization, expandable system design and long service life. This equipment can produce 2,230 Nm³/h Hydrogen at a pressure of 30 bar(g) with a power consumption of 4.7 kWh/Nm³. Maximum hydrogen production capacity: 19400Nm3 /h. It is often used in different fields such as steel mills, oil refineries, chemicals, motor vehicles or energy as a lowcost and reliable green hydrogen production option.

Electrolytic process of alkaline solution

SYSTEM FEATURES

1. Proven technology with demonstrated system runtime of more than 30 years;

2. Lowest electrolyzer costs reduce capital requirements;

3. Renewable hydrogen is delivered at a pressure of up to 30 bar (g);

4. 10 MW modular design enables effective scaling to large electrolysis capacities;

5. Easy integration into any environment – whether industrial or greenfield.

PARAMETER

| Model | HA150 | HA300 | HA500 | HA1000 | HA2200 | HA3900 |

|---|---|---|---|---|---|---|

| Net Production Rate | ||||||

| Nm³/h | 50-150 | 150-300 | 300-500 | 600-1000 | 1800-2200 | 2400-3900 |

| kg/24h | 108-324 | 324-647 | 647-1080 | 1296-2160 | 3888-4752 | 5184-8424 |

| Production Capacity Dynamic Range | 15 - 100% | 15 - 100% | 15 - 100% | 15 - 100% | 15 - 100% | 15 - 100% |

| Average Power Consumption at Stack | 3.8-4.4 kWh/Nm³ | 3.8-4.4 kWh/Nm³ | 3.8-4.4 kWh/Nm³ | 3.8-4.4 kWh/Nm³ | 3.8-4.4 kWh/Nm³ | 3.8-4.4 kWh/Nm³ |

| H2 Purity | 99.9±0.1% | 99.9±0.1% | 99.9±0.1% | 99.9±0.1% | 99.9±0.1% | 99.9±0.1% |

| H2 Purity (with Optional Purification) | 99.99-99.999% | 99.99-99.999% | 99.99-99.999% | 99.99-99.999% | 99.99-99.999% | 99.99-99.999% |

| O2-Content in H2 | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v |

| H2O-Content in H2 | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v | < 2 ppm v |

| O2 Purity | 99.5±0.2% | 99.5±0.2% | 99.5±0.2% | 99.5±0.2% | 99.5±0.2% | 99.5±0.2% |

| Delivery Pressure | 1–200 barg | 1–200 barg | 1–200 barg | 1–200 barg | 1–200 barg | 1–200 barg |

| Dimensions | ~150m2 | ~200m2 | ~225m2 | ~350m2 | ~375m2 | ~770m2 |

| Ambient Temperature | 5-35℃ 41-95℉ | 5-35℃ 41-95℉ | 5-35℃ 41-95℉ | 5-35℃ 41-95℉ | 5-35℃ 41-95℉ | 5-35℃ 41-95℉ |

| Electrolyte | 25% KOH | 25% KOH | 25% KOH | 25% KOH | 25% KOH | 25% KOH |

| Feed Water Consumption | 1.85 m³/h | 1.85 m³/h | 1.85 m³/h | 1.85 m³/h | 1.85 m³/h | 1.85 m³/h |

APPLICATION

1. Steel

Direct reduction of iron, blast furnace injection, protective atmosphere, etc.;

2. Refineries

Desulphurization, hydrocracking, hydrogenation, etc.;

3. Chemicals

Ammonia production, hydrogenation, isotope separation, etc.;

4. Mobility

Fuel cell vehicles for road and rail;

5. Energy

Industry and space heat, power balancing, etc.